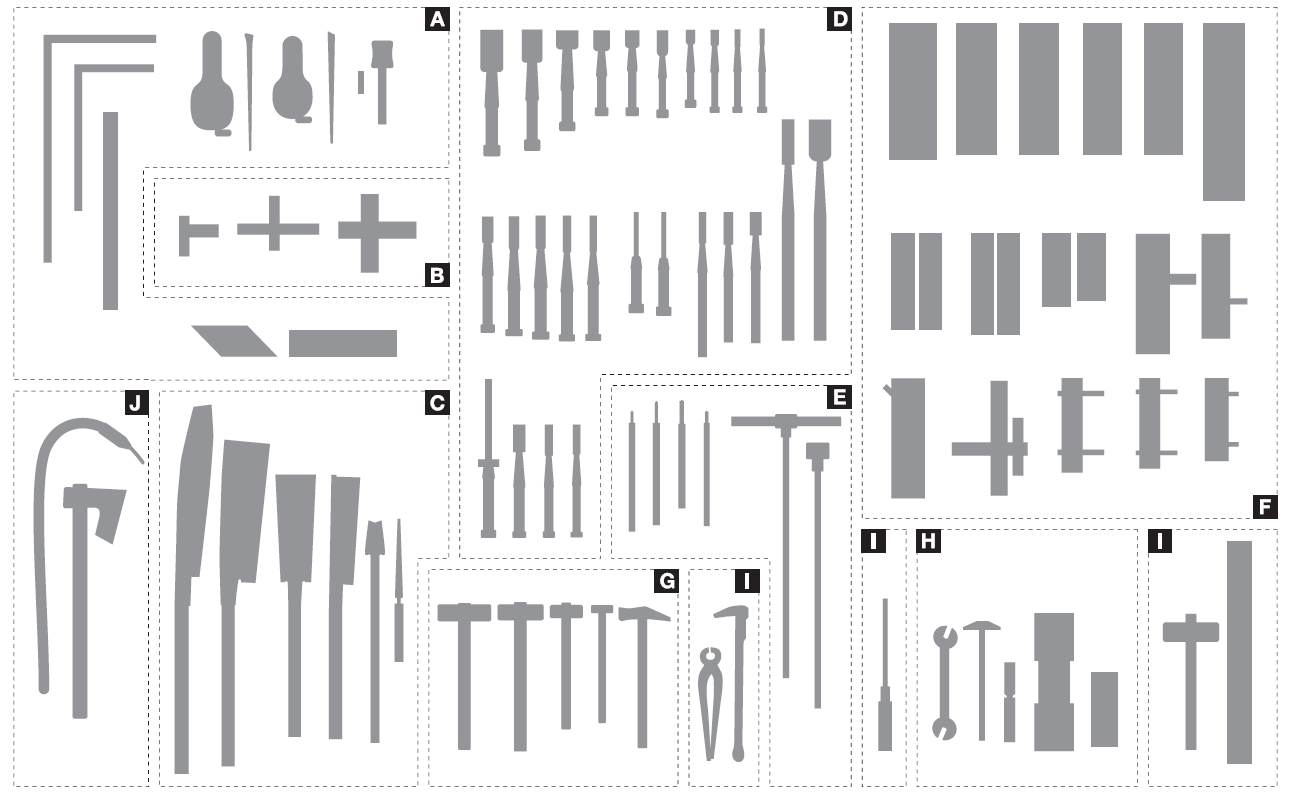

Masters of Carpentry | Japanese Carpentry Tools

A. Sumikake Dōgu / Marking Tool

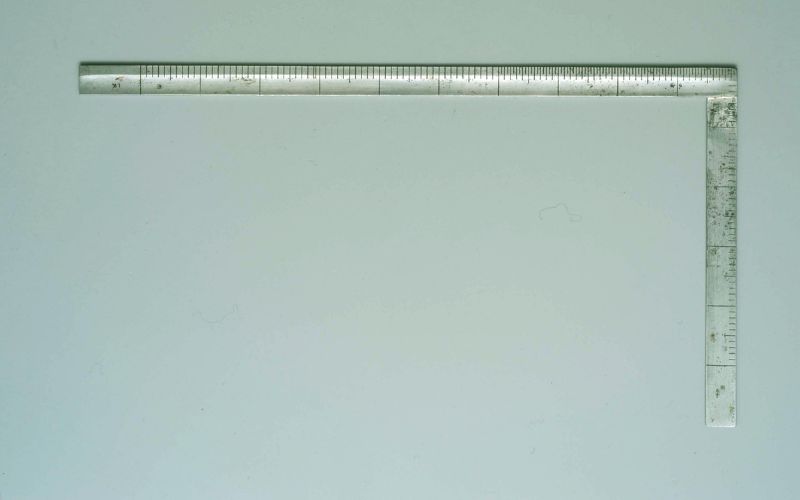

Sashigane / Carpenter’s Square

The sashigane (Carpenter’s square) is used for measuring lengths and angles. This L-shaped square ruler is referred to in various ways: sashigane, kane-shaku, magarigane. The long side of the L is called the nagate or choshi (long branch), and the short side is called the tsuma-te or tanshi (short branch). When the long side is held vertically and the short side is positioned to the right, this is considered to be the front (omote), with the opposite side is called the back (ura). The front side, typically has standard graduations (omote-me), where as the back side features scales that are √2 times (kaku-me) or π times (maru-me) the standard measurements.

Read more.

In addition, though not in contemporary use, there exists a scale obtained by dividing 1 shaku - 2 sun (traditional Japanese scales) by 8, marked on the sashigane by letters with prophetic significance instead of numbers (mon-shaku or rohan-shaku).

Sashigane are also used as an aid to mark lines on a variety of materials. For carpenter's, it is an indispensable tool, treated with great respect; stepping on one at a job site was promptly admonished with angry shouts.

Traditionally made of steel or brass, stainless steel was introduced in the early 20th century. Some brass sashigane are reinforced with triangular steel at the right angle to avoid unwanted distortion (kado-tetsu-iri).

Makigane / Small Carpenter’s Square

The makigane is slightly shorter and thicker than the carpenter’s square (sashigane), though some use the same scale. They are made of iron, brass, or stainless steel and are mainly used to check right angles.

Suiheiki / Spirit Level

Two level vials are integrated into a wooden ruler with metal strip along one side providing an accurate reading surface. The motion and position of bubbles in the vials are used to check the accuracy of horizontal and vertical alignment.

Sumitsubo / Inkpot

The sumitsubo (Lit. Inkpot) is used to accurately mark long, straight lines on surfaces. A thread (tsubo-ito) is tied to a small round wood weight with a needle fixed at the end (karuko). The other end of the thread is wound around a spool (itomaki-guruma). To mark a line, the thread is passed through the reservoir (ike) containing ink and through a small opening (itoguchi), at the end of the inkpot (sumitsubo). The ink is stored in the ike soaked in silk wadding. Silk threads are used as the tsubo-ito.

Shutsubo / Red Inkpot

Shutsubo are inkpots, similar to sumitsubo, that use red ocher (benigara) instead of black ink. Red pigment is used when carpenters need to mark polished natural tree trunks that still have their bark, because the pigment can be easily washed away with water.

Sumisashi / Bamboo Pen, Sumisashi / Red Bamboo Pen

A sumisashi is a type of pen generally made of bamboo. One end has a spatula for drawing lines, and the other is shaped to a point for writing symbols or letters. It is used together with an inkpot, either a sumitsubo or shutsubo. The spatula end is 4 to 6 inches wide, featuring a diagonally cut tip with lengthwise slits that are 1/2 to 1 inch deep. This end is moved along a sashigane to draw lines. Some experts split the tip extremely finely (30-40 slits) to form a brush.

Itomaki / Reel

An itomaki, or reel with line, is a tool for checking horizontal surfaces. It is used to connect horizontal points measured with a spirit level for drawing reference lines.

Tomegata-jōgi / Miter Joint Gauge, Kiguchi-jōgi / Block Gauge

The miter joint gauge, or tomegata-jōgi is a thin lozenge-shaped splint board that slants at a 45-degree angle so that the carpenter can set the saw at 45 degrees and cut the wood at this angle. The kikuchi-jōgi, or block gauge, is made of two rectangular boards attached to each other, forming a right angle. It is used for cutting right angles.

B. Suji-kaki-biki / Marking Gauge

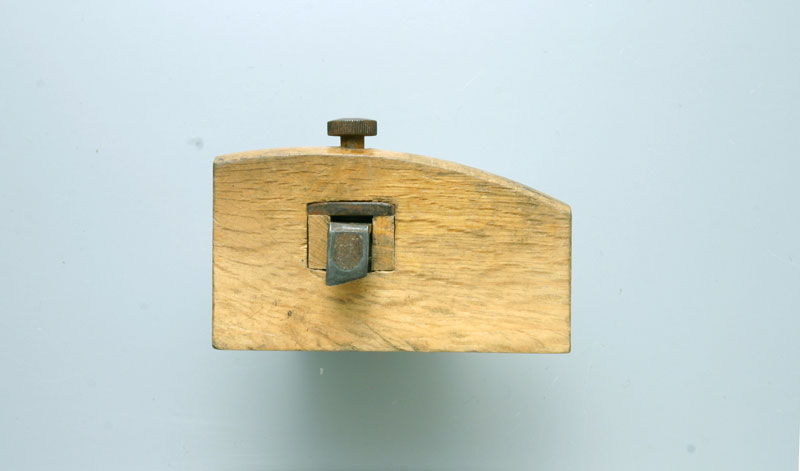

Kama-kebiki / Double Marking Gauge

The kama-kebiki, or double marking gauge, is equipped with two L-shaped metal bars with blades at the tip of the short end. The long arms of the L-shaped bars are fastened with a screw through the body of the gauge and travel above the timber parallel to the surface, with the blades at the tip of the short end scoring the surface. This tool is used when a protrusionfrom the surface of the timber may be an obstruction.

Suji-kebiki / Marking Gauge

A suji-kebiki, or marking gauge, is used to scribe lines parallel to the baseline of the timber. There are different marking gauges (kebiki) designed for different purposes. Gauges with two rods (nihonsao-suji-kebiki) enable marking of two different lines simultaneously, or turning the kebiki around and repeating the action with the second blade on the opposite end. Gauges with long rods (nagasao-kebiki) allow the carpenter to mark lines which are farther from the edge.

Wari-kebiki / Splitting Gauge

The wari-kebiki, or splitting gauge, is slightly larger and sturdier than the suji-kebiki and is used for cutting thin timber lengthwise.

C. Nokogiri / Saw

Anahiki-noko / Rounded-Nose Roughing Saw

The round-nosed roughing saw, known as the hanamaru-nokogiri or anahiki-nokogiri, is about 15.5 to 19 inches long and is used for rough work such as cutting off the ends of a log. Since it has ibarame teeth (inclined wedge-shaped teeth with sharpened tips), it is also used for cutting materials diagonally.

Hikikiri / Standard Crosscut Saw

The hikikiri, commonly known as the kiri, is a standard crosscut saw measuring from 10 to 15.5 inches long, and is principally used for crosscut sawing.

Ryōba-noko / Double-edged Saw

The ryōba-nokogiri is a saw generally 9.5 to 14 inches in length with a double-edged blade with both ripsaw and crosscut sawing teeth. From 1898, it became popular throughout Japan.

Dōzuki-noko / Back Saw

The dōzuki-nokogiri is a back saw with a 9.5 to 12 inch long blade that is thin and reinforced along the non-cutting edge. It has fine teeth that create a precise and smooth cut, which makes it suited for precision work.

Azebiki-noko / Double-Edged Saw

The azebiki-nokogiri is a double-edged saw generally 2.5 to 4 inches long with cutting teeth and a cutting blade on both sides that is short and curved. It is used for cutting holes into wood. It spread throughout Japan from the Meiji period (1868-1912) onwards.

Hikimawashi-noko / Keyhole Saw

The hikimawashi-nokogiri is a keyhole saw that is used to work on curves that penetrate through the material. It is generally 7 to 8 inches long and cuts on the pulling stroke.

D. Nomi / Chisel

Hiro-nomi / Wide-Blade Chisel

These hiro-nomi are striking chisels, a type of hon-tataki nomi striking chisel with a blade width greater than 1.5 inches. The blade width ranges from 1.5 to 2.5 inches. They have a relatively thin blade (middle of the thinness scale) and are used for shaving surfaces in parallel to the woodgrain.

Ōire-nomi / Butt Chisel

Ōire-nomi are butt chisels with a relatively thinner, shorter blade tip and shank (around 2 inches). and a blade width generally ranging from a very fine 1/10 of an inch, to 2 inches. They are used for detailed carpentry work.

Hontataki / Striking Chisel

Hontataki-nomi are striking chisels with a sturdy structure and thick, long blades. The shank length ranges from 2.5 to 3 inches and the blade widths from 1/10 of an inch to 1 inch. They are used for rough work such as boring holes into structural materials.

Mukōmachi-nomi / Mortise Chisel

Mukōmachi-nomi are mortise chisels with a blade width generally ranging from 1/20 to 3/4 of an inch. The blade tip is thick and narrow (the same width as the shank) and has a rectangular shape in cross-section that makes it particularly robust. It is mainly used for carving grooves into doors, panels and screens (tategu), so it is also called the tateguya-nomi (door-carpenters’ chisel).

Kote-nomi / Trowel Chisel

The kote-nomi, or trowel chisel, has a blade the shape of a traditional Japanese smoothing iron (kote) and a long shaft, The blade width generally ranges from 1/4 of an inch to 1 inch. These chisels are used for finishing the bottom surfaces of grooves created by other chisels. It usually not struck and does not have a cap (katsura) on the handle.

Ari-Nomi / Dovetail Chisel

The ari-nomi, or dovetail chisel, has a relatively long blade that is triangular in shape in cross-section and a blade width generally ranging from 1/10 of an inch to 1 inch. It is used for hand finishing acute angles in corners. It usually does not have a cap (katsura) on the handle.

Tsuki-Nomi / Paring Chisel

The tsuki-nomi is a pairing chisel with a long, relatively thin blade, and a blade width generally ranging from 1/10 of an inch to 2.5 inches. It is used for finishing processed surfaces of structural materials. Its long shaft and handle facilitates the paring of timber. The chisel is held with two hands and thrust against the timber. It usually does not have a (katsura) on the handle.

Tsuba-nomi / Sword-Guard Chisel

The tsuba-nomi, or sword-guard chisel is named for the sword-guard (tsuba)-like protrusion at the base of the shaft. It is used for boring holes for large nails. Once the chisel is struck into the timber to the required depth, it is ejected by hitting the sword-guard upwards. The blade can be double-edged.

Ura-Maru-Nomi / Gouge

The ura-maru-nomi is a gouge with a curved blade and cutting edge. It is used for shaving or carving curved surfaces. The typical blade width ranges from 1/10 of an inch to 1.5 inches.

E. Kiri / Gimlet

Yohō-giri / Four-faces Gimlet

A yohō-giri, or four-faced gimlet, is used for boring holes for wooden or bamboo nails.

Mitsume-giri / Three-eyed Gimlet

A mitsume-giri, or three-eyed gimlet, is also used for boring holes for nails.

Tsubo-giri / Pot Gimlet

A tsubo-giri, or pot gimlet, is used for boring a mortise.

Nezumiha-giri / Mouse-Teeth Gimlet

A nezumi-ha-giri, or mouse-teeth gimlet, is used for boring holes into bamboo.

Bōruto-kiri / Screw Auger

The screw auger referred to as the bōruto-kiri or sometimes gimune has a T-shaped handle and is suited for boring large, deep holes such as mortise holes into beams and joists, or holes for bolts.

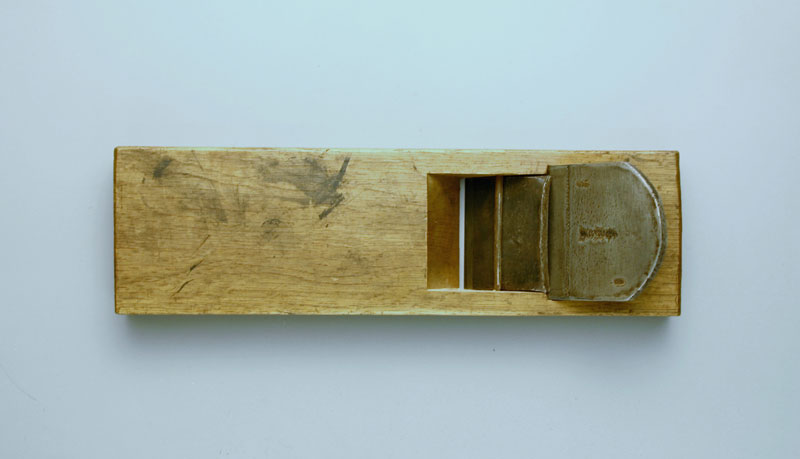

F. Kanna / Plane

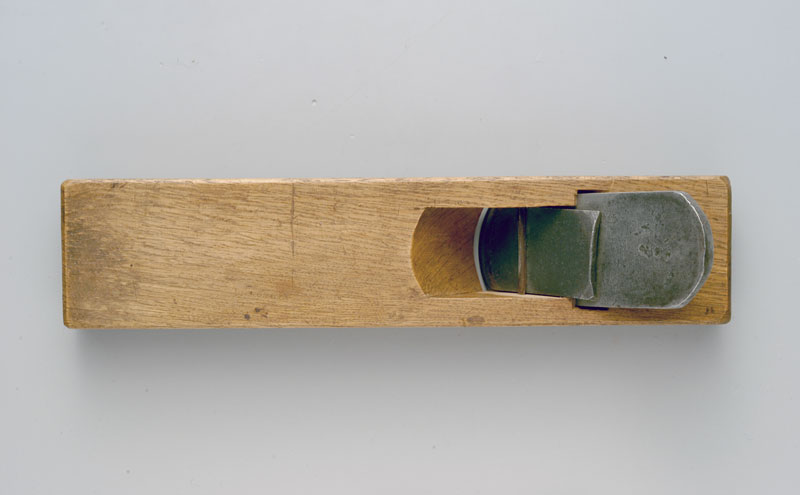

Shiage-ganna / Finishing Plane, Muratori-ganna / Uneven Smoothing Plane, Jyōshiko-ganna / Finishing Plane, Ara-shiko-ganna / Rough Smoothing Plane, Chu-shiko-ganna / Middle Smoothing Plane, Nagadai-ganna / Jack Plane

Wood planes or "Kanna" (sometimes pronounced "ganna" based on dialect and usage), more formally called hira-ganna (Lit. "flat plane" or "smooth plane"), can be subdivided into various types depending on their function at different stages of finishing a surface.

The arashikō-ganna with a relatively longer protruding blade length and width is used at the beginning to pare thicker shavings off rough surfaces. Then the chūshikō-ganna with a less protruding and narrower blade is employed to prepare the surface for final smoothing with a finishing plane (shiage-ganna or jōshikō-ganna) which has an even narrower and shorter blade.

A kanna, or plane, with a blade longer than 3.5 inches is called a taihō (cannon), while one with a small base and a blade shorter than 2 inches is called a ko-ganna (small plane), and one of a remarkably small size is called a mame-ganna (bean plane).

(These namings apply to all kanna types and not just to hira-ganna.)

Furthermore, a kanna with a normal-sized blade but with a long base measuring around 16 inches is called a nagadai-kanna (a long-base plane, or Jack Plane in English), and one with a base measuring around 13.5 inches is called chūdai-kanna (mid-length base plane).

Sotomaru-ganna / Rounding Plane, Uchimaru-ganna / Hollow Plane

A plane with the bottom curved outward is literally called the “outwardly round plane” or sotomaru-ganna and is used for shaving concave surfaces. A plane with the bottom curved inward is called a uchimaru-ganna and is used for shaving convex surfaces. The cutting edge of the blade is also curved, similar to the base of the plane. Depending on the type of curvature, there are several variations such as fukamaru (for both sotomaru and uchimaru types) and jikumaru (for sotomaru types).

Kiwa-Kanna (Migi-gatte) / Corner-Cutting Plane (Right-Handed Type),

Kiwa-Kanna (Hidari-gatte) / Corner-Cutting Plane (Left-Handed Type)

A kiwa-gana (corner plane) has the blade tilted diagonally so that the cutting edge extends out to the edge of the plane body. This design enables precision corner work and in tight spaces. Depending on the direction of use, it is called right-handed (when the blade extends to the left) or left-handed (when the blade extends to the right). Some versions come with an adjustable guide attached to the bottom, allowing you to modify the width of the cut by adjusting the guide with screws.

Soridai-ganna / Compass Plane, Shiho-soridai-ganna / Compass Plane

The compass plane, or soridai-ganna,has a smoothing plane blade set into a relatively smaller base that is curved at the bottom, like a spoon. It is used for paring down significantly curved surfaces. A plane with a base that is curved both in section and cross-section is called the shihō-sori-kanna (4-directionally curved plane) and a plane that is curved outwards in section but inwards in cross-section is called the funazoko-ganna (bottom-of-a-ship plane). Most are small in size.

Wakitori-ganna / Side Shaving Plane, Hibukura-ganna / Pointed Side Shaving Plane

These planes are used for shaving and finishing the lateral sides of a groove (waki). The blade is set so that the cutting edge extends to the side of the plane's body. There are two types: right-handed and left-handed, depending on the direction of use. The cross-section of the plane is designed with a slightly wider, more durable upper part, and it gradually narrows toward the bottom, which has a stepped shape.

Those with a narrow, flat bottom surface are called wakitori-ganna and are used for shaving the sides of wider grooves, while those that narrow down almost to a pointed edge are called hibukura-ganna and are used not only for shaving groove sides but also for internal angles.

Soko-jakuri-ganna / Plow Plane

The soko-jakuri-ganna is a plow plane used to smooth and finish the bottom surfaces of grooves in a doorsill or lintel. The blade is generally similar to that of a chisel and its width ranges from 1/4 of an inch to just over an inch, but most measure between 1/2 to 1 inch.

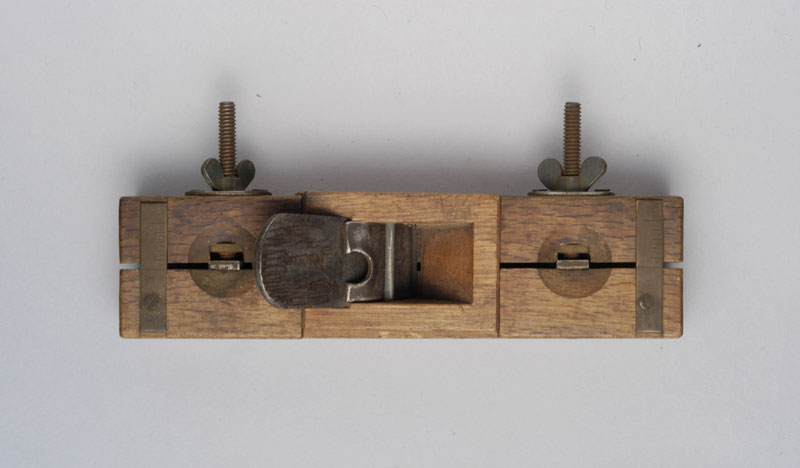

Motoichi-jakuri-ganna / Wide Groove Plane (Plow Plane)

The motoichi-jakuri-ganna, or wide-groove plane, has the same function and use as an ara-shakuri-ganna, that is, to roughly shave dovetail joints, but it has guides at the sides of the base that are adjusted depending on the depth and length of the groove. The blade width generally ranges from 1/2 to 1 inch.

Ari-jakuri-ganna / Sliding-Dovetail Plane

The ari-jakuri-ganna, or sliding dovetail plane, is used for shaving the tongue and grooves of dovetail (ari) joints. There are two types: male and female. The male plane (for carving the protruding tenon of the dovetail) has a diagonally cut indentation in the base of equal width to the blade. The female plane has a diagonally cut bottom to carve the concave mortise of the joint. There is also a combination dovetail plane that can be used for both the male and female portions of the joint.

Kikai-jakuri-ganna / Dovetail Plane

The kikai-jakuri-ganna, or dovetail plane, is used for carving narrow grooves. Its name comes from the mechanical, or kikai in Japanese, look of its structure. It is equipped with a guide on the base with a screw that can be adjusted to set the width of the groove. The blade width generally ranges from to 1/10 to 1/2 of an inch. It was called the koana-zuke until the introduction of the screw mechanism.

Mentori-ganna / Molding Plane

In mentori-ganna, or molding planes, the bottom surface of the base and the blade are cut into the shape of the required chamfer (a beveled edge that transitions between two surfaces). Some are equipped either with a fixed triangular guide, or an adjustable free-form guide, that helps the plane stabilize the wood while shaving off a corner as well as determine the depth of the cut. Some are equipped with two blades to carve out complex shapes.

G. Gennō / Hammer

Ryoguchi-gennō / Double-Faced Hammer

The striking surfaces of the ryōguchi-gennō, or double-faced hammer, have different shapes; one is flat and the other bulges out slightly in the center. The flat side is used for striking chisels and driving nails, while the convex side called the kigoroshi-men (literally the “wood killing surface”) is used to flatten timber surfaces. It is also used for lightly tapping the final strike when driving a nail to avoid leaving marks on the timber.

The size of a gennō (hammer) is measured in terms of weight and the traditional Japanese unit monme is still being used today. Gennō used for rough work usually weigh 100 monme (3/4 lb.). The handle is typically made of oak.

Sakigiri-kanazuchi / Pointed Hammer

Kanazuchi are used principally for driving nails, and unlike the gennō has one flat striking surface and one pointed striking surface to drive nails into narrow corners. The most representative types are the sakigiri-kanazuchi, shitahara-kanazuchi and yonbun-no-ichi-kanazuchi (quarter hammer).

H. Maintenance Tools Toishi / Whetstone or Sharpening Stone

Ryōguchi-spanner / Double Open-Ended Wrench

The ryōguchi-spanner or double open-ended wrench is a tool for working with bolts and nuts. It has a mouth at both ends and is identical to the Western version.

Asari-tsuchi / Asari Hammer

The teeth of a saw wear down over time, causing the cutting performance to deteriorate. The periodic sharpening of saw teeth is called metate. First the blade is placed on an anvil and is straightened by hammering with a hasuchi (blade mallet) to correct any warping. Next the teeth are set or aligned. There are two methods to the set the teeth. One method uses a saw setter, or meburi, where the saw teeth are clamped in the groove at the tip of the tool and bent left and right to create the correct set. The other method uses an asari hammer, where the saw teeth are placed on the edge of the anvil and every other tooth is hammered. After flipping the saw over, the teeth that were not previously hammered are struck, allowing the set to be adjusted on both sides. The teeth are then sharpened with a saw file.

Metate-yasuri / Saw File

When sharpening the teeth as part of the metate process the saw blade is fixed in a saw clamp with only the teeth exposed, a wedge is then inserted in the bottom of the clamp to secure the blade. Depending on the application of the saw, the grinding angle and the inclination of the cutting edge are filed and sharpened. There are various types of saw files, or yasuri, depending on the application. Cutting files, are used for general sharpening and for relatively large saw teeth grinding files, may be required.

Shiageto / Finishing Stone

The finishing stone, known as shiageto or awaseto, is used for the final finishing/sharpening of a cutting edge to a mirror-like surface. The hardness of the stones vary depending on the purpose. Finishing stones include uchigumori-do and suita-to. Most finishing stones come from Kyoto, with stones from the Nakayama area, referred to as "Motoyama", being particularly renowned and becoming synonymous with finishing stones.

Dainaoshi-ganna / Sole Tuning Plane

A dainaoshi-ganna is a sole-turning plane with a single blade set at almost a right angle (90 degrees) to the body. It is shorter than a normal flat plane,or kanna. It is a critical tool for finishing and adjusting the bottom surface of other planes, which determines the quality of the shaving. It is also used for shaving harder woods such as red sandalwood or ebony.

I. Other Tools

Kuginuki or Enma / Pincers

Enma, also known as kuginuki are pincers that are used to pinch and pull out a nail when the head is exposed. Japanese nails, with a square cross section, have heads that are simply bent flattened metal making them difficult to be hooked and pulled out. Therefore, an enma is used. The curved part grabs the nail and becomes the fulcrum of the lever. When the nail is long or deeply embedded, a block of wood is placed against the curved side to use leverage for easier extraction.

Kuginuki or Kajiya / Crowbar

There are two types of crowbars used to remove nails from wood - a kajiya and a bar. The kajiya has both ends split to grip nails. The head of the nail is hooked in the split and pulled out using the principle of leverage, as with the enma.

The bar has a long flat handle. This flat portion is also used for dismantling work such as inserting between the nailed sections and peeling them apart.

Flat-Blade Screwdriver

The flat-blade screw driver is identical to the Western version.

Kitsuchi / Mallet

The kitsuchi, or kizuchi, is a mallet used principally for extracting or inserting the blade of a plane. The edge of the plane is tapped when extracting the blade, and the blade itself is tapped when inserting it into the plane.

J. Ono / Axe

Chōna / Adze

The adze, or chōna is primarily used for rough carpentry and wood scraping. It is ideal for tasks such as cutting lumber into square timbers, trimming rafter bases, rough-cutting gables, and finishing alcove pillars, where chisel marks are often left decoratively.

An adze is used by holding the handle with both hands and striking the blade down toward the user. It is designed to split and shave wood along the grain. For finishing work, a thin, long chisel is preferred. Most adze blades are double-edged, with two main types: double-sided, where both sides of the blade are symmetrical along the centerline, and single-sided, which only one side is sharpened.

Daiku-masakari / Carpenter's Hewing Axe

Masakari are hewing axes used mainly to smooth down and finish timber. The carpenter's broadaxe, or daiku-masakari, is used for rough carpentry work or for making wedges from scraps of wood.